March 3, 2021 —  When you picture solar power, chances are you conjure up images of large solar panels spanning the length of a rooftop or a large solar farm out in a field. But what if you could put a solar panel in the sunroof of a hybrid car, on a tent or within the windows of an office building? What if you could power a vaccine refrigerator in a remote place with a flexible solar panel that could be shipped in a mailing tube? These are just a few possible applications of a relatively new technology known as organic solar cells (OSCs) — new, at least, when compared with silicon solar technology, which has been around since the 1950s.

When you picture solar power, chances are you conjure up images of large solar panels spanning the length of a rooftop or a large solar farm out in a field. But what if you could put a solar panel in the sunroof of a hybrid car, on a tent or within the windows of an office building? What if you could power a vaccine refrigerator in a remote place with a flexible solar panel that could be shipped in a mailing tube? These are just a few possible applications of a relatively new technology known as organic solar cells (OSCs) — new, at least, when compared with silicon solar technology, which has been around since the 1950s.

Like traditional silicon solar technology, OSCs turn the sun’s energy into usable electricity. But they are far more versatile than conventional solar photovoltaics. OSCs are lightweight and flexible and can be made to be semitransparent or in various colors. These qualities give them potential applications for textile, vehicle and building-integrated solar cells, and for creating power in areas where it does not exist.

Unique Applications

While additional funding and research are needed to bring OSCs to the commercial market, experts agree they will play an important role in the future of solar technology. That said, they won’t replace or compete head-to-head with silicon solar cells. “We shouldn’t expect to see expansive fields of OSCs, like those that generate gigawatts of power at silicon solar farms,” says Seth Marder, a chemistry professor at Georgia Tech. Silicon solar is suitable for providing large-scale solar power, while OSCs have other unique strengths that guide its real-world applications.

Two unique features of OSCs are their thinness and flexibility. While a typical silicon solar cell is about as thick as the average width of a human hair, most OSCs are roughly a thousand times thinner. Because of their thinness and flexibility, OSCs can be fabricated on curved surfaces and flexible backings. For example, they can be patched or integrated into the fabric of tents, backpacks and even clothing. Most of these products are still under development and occupy a niche market, but they demonstrate the innovative creativity that OSCs provide. With OSC technology, the possibilities for where solar cells can be used has been greatly expanded beyond just rooftops and solar farms.

As a result of their unique features, organic solar cells have a number of potential applications, including integration into windows to generate energy from sunlight. Photos courtesy of MaterialDistrict

OSCs also can be made transparent, semitransparent or in various colors. As a result, there are many potential applications for architectural use. For example, transparent OSCs could be integrated into windows to generate energy from sunlight that might otherwise warm a room and contribute to higher air conditioning costs. Franky So, a materials science and engineering professor at North Carolina State University, offers yet another application: OSCs could be used in sunroofs to help power electric and hybrid vehicles.

Additionally, low up-front investment and potentially low product shipping costs make OSC technology accessible to communities in developing countries that lack access to an electrical grid and the financial means to build one. OSCs have a unique ability to “bring power where power does not exist,” explains Malika Jeffries-EL, an associate professor of chemistry at Boston University. In these instances, OSC technology could provide essential electricity in the smaller quantities needed for tasks such as lighting, charging cell phones, and refrigerating medications and vaccines.

Another selling point of OSCs is that they are less energy intensive to manufacture than are silicon solar cells. Extremely hot furnaces — upwards of 1,500 °C (2,700 °F) — are needed to generate high purity silicon for silicon solar cells. By comparison, large-scale OSCs can be manufactured by simply printing the layers of the cell onto a backing in a process similar to that used to print newspapers. Because this process consumes less energy, OSCs have a significantly shorter energy payback time than silicon cells. In other words, OSCs require a shorter amount of time to generate the amount of energy it took to manufacture them.

How It Works

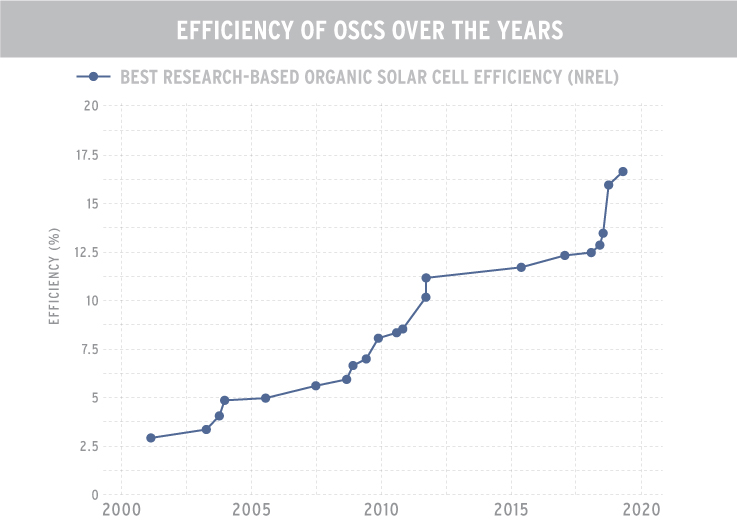

The first organic solar cell was developed in 1958, but it wasn’t until the 2000s that OSCs saw a significant increase in efficiency. This improved OSC technology emerged from the field of organic light-emitting diodes, commonly known as OLEDs. OLED technology is used for many television and phone screens on the market today. In an OLED screen, a layer of organic molecules (molecules composed primarily of carbon and hydrogen atoms) emits light when an electric current is applied. OSCs work in essentially the opposite way — the layer of organic molecules generates an electric current when exposed to light.

An organic solar cell is made up of multiple layers of materials, one of which is the acceptor layer. When sunlight hits the cell, an electron is released from the layer of organic molecules, and the job of the acceptor is to pass that electron on to the electrode. This process causes a build-up of charge, which is what generates electricity.

With the development of non-fullerene acceptors, the efficiency of OSCs increased sharply. Graph courtesy of Dr. Felipe Larrain

Traditionally, the most commonly used acceptors in OSCs were materials based on fullerene — a molecule composed of 60 carbon atoms joined together in a structure that resembles a soccer ball. However, with fullerene acceptors the efficiency of OSCs was limited to around 10%. In other words, only 10% of the sunlight hitting the solar cell was converted into electricity. Researchers therefore set out to explore new types of acceptor layers as a means to increase OSC efficiency.

The breakthrough that permitted OSCs to achieve higher efficiencies was the development of non-fullerene acceptors (NFAs). With NFAs the efficiency of OSCs increased sharply — up to 18% in just a few years. This has brought OSCs to the lower end of the 18% to 22% efficiency of the average commercially available silicon solar cell. This uptick in efficiency has exceeded the expectations of many experts, some of whom began working in the field when the efficiency of OSCs hovered around just 3%. “If 10 years ago you had told me we would have organic solar cells of 18% efficiency, I would have laughed,” Marder says.

Barriers to Overcome

There is still much work to be done before OSCs can be widely marketed. One of the biggest challenges is the solvents used in the manufacturing process. Most of the top-performing OSCs are made using chlorinated solvents, which present both health and environmental hazards. “When scaling up OSC manufacturing, you have to consider the exposure of people who will be working in the manufacturing plants,” says Bernard Kippelen, a professor of electrical and computer engineering at Georgia Tech. The research to date has focused largely on obtaining increasingly higher efficiencies, but as Kippelen says, “we need an approach that goes well beyond just one number.” To make OSCs a viable technology, the manufacturing process must be optimized to make it safer and more cost-effective.

Another barrier to the mass production of OSCs is the difference between the efficiencies of individual cells tested under ideal lab conditions, and the efficiencies that have been demonstrated for larger modules. Individual cells can have high efficiencies, but assembling multiple cells into modules, panels or arrays requires additional electrical connections that will decrease the efficiency. However, as Kippelen points out, these sorts of disparities are expected. “It takes some time before the increases in cell efficiency are reflected in the efficiencies of modules coming off the manufacturing lines,” he says. “The same was true of silicon solar cells.”

Funding for OSC research is another concern. In the United States, much of the funding for solar cell research comes from government agencies, such as the Department of Energy. However, according to Kippelen “a lot of funding sources kind of dried up to do research on OSC,” due to the emergence of a rapidly expanding class of solar cells called perovskites. “There has been a lot of excitement around the use of perovskites because their efficiency is even higher than silicon in some cases,” says Kippelen. However, even as funding for OSCs has decreased in the U.S., China continues to spearhead OSC research and development. “The amount of work [on OSC research] in the United States is a tiny fraction of the amount of work in China,” Marder says. “People in China are going full blast on this.”

Reasons for Optimism

Future world energy consumption will continue to rise, especially as developing countries aspire to the same benefits of on-demand energy production that developed countries enjoy. Researchers like Marder, Kippelen, Jeffries-EL and So say OSC technology has the potential to play a unique and important role in the global transition toward renewable energy. The recent increase in OSC efficiency to 18% has many researchers working to advance this technology, and scientists are now looking into tandem OSCs (which use two different materials that absorb distinct wavelengths of sunlight) to capture even more energy. Some are hopeful that this development could increase OSC efficiency even further — up to 20%.

Kippelen calls for a long-term view of OSC technology. “Solar technology is going to be around for a long time,” he says, “and I truly believe OSC, with time, will establish itself as a really important technology.”

Related Posts

Ensia shares solutions-focused stories free of charge through our online magazine and partner media. That means audiences around the world have ready access to stories that can — and do — help them shape a better future. If you value our work, please show your support today.

Yes, I'll support Ensia!