July 1, 2014 — Editor’s note: The following is adapted with permission from Creating a Sustainable and Desirable Future: Insights From 45 Global Thought Leaders, edited by Robert Costanza and Ida Kubiszewski, copyright 2014 by World Scientific Publishing Company, Inc. The piece originally appeared in Solutions.

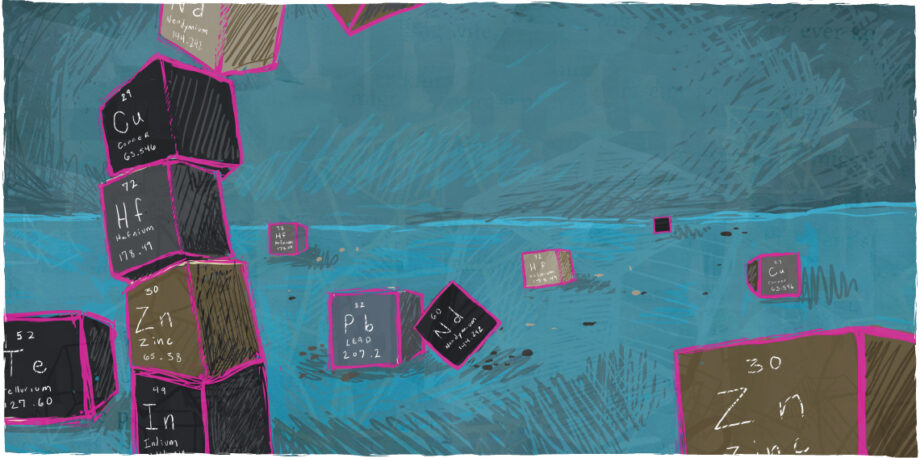

The Earth is finite, and so are the chemical elements of which it is composed. Those elements, represented by the symbols that fill the boxes of the periodic table, fuel all human consumption. Yet we are mining and redistributing these fundamental elements at such a rapid rate that many are already in short supply or likely to become so in the next few decades. To maintain supply lines to the dinner table and to industry, we must completely reframe our understanding of mining, consumption, human environments and waste, recognizing that the accessible elemental resources of our future are largely stored above ground in the familiar objects of our daily lives.

Chemical elements are being shifted out of their natural reserves — in deposits in the Earth’s crust — into human consumables at a remarkable rate. As far back as 20 years ago, a study conducted at Kyoto University concluded that 80 percent of the world’s mercury reserves; 75 percent of its silver, tin and lead; 70 percent of gold and zinc; and 50 percent of copper and manganese had already been processed through human products. (The term “reserves” is generally taken to mean the identified geological source of an element or mineral that, at the specified time of the determination, could be extracted and produced economically.)

Some of the elements under serious threat are familiar. Silver, for example, which is used as a catalyst for a wide variety of chemical reactions in manufacturing, and zinc, used to protect iron and steel against corrosion. Other, less well-appreciated elements that form the basis of modern life are also being consumed unsustainably, including tellurium and hafnium, both of which are used in electrical devices and special metallic alloys. Indium, a common ingredient of solar cells and computer displays is on the endangered list, as is neodymium, an important building block of magnets used in many industries (e.g., for wind turbines, car batteries and computer hard-disk drives), as well as in ceramics and glasses.

Unfortunately, accurate estimates of the exact amount of the elements currently in human use around the world are hindered by large gaps in our understanding. Reasonably robust global estimates do exist for the amount of aluminum, lead, copper, zinc and iron in use. Of these, lead, copper and zinc are on the endangered list. Comparison with underground global ore reserves indicates that, as a fraction of all past and current such reserves, 45 percent of lead, between 33 and 43 percent of copper, and at least 45 percent of zinc was already above ground and in use by 2005.

The good news is that some industries, governments, scientists and local communities have already begun serious programs to speed sustainable use of these and other natural resources.Between 1950 and 2000, the world’s population slightly more than doubled, while the production of precious metals grew fivefold. Between 1947 and 2000, per capita zinc consumption in the United States rose from 6.3 to 210 kg. For comparison, the average citizen of Cape Town, South Africa, used about 18 kg of zinc in 2002. In the future, if citizens in developing countries use metals to the same extent and in the same way as those in developed countries currently do now, even more metals would be stored in use in human products — between three and nine times more.

Already Begun

The good news is that some industries, governments, scientists and local communities have already begun serious programs to speed sustainable use of these and other natural resources.

The chemical industry is in a key position. BASF, the world’s largest diversified producer of chemicals, released a long-term business strategy in which the company indicates that it intends to use sustainability as a strategic driver moving forward, in particular re-mining the rare earth elements from its own activities. Between 1990 and 2010, 3M reduced the tonnage of waste it produced (defined primarily as unused raw materials) per sales dollar by 66 percent. By reformulating its products, redesigning equipment, modifying processes and reusing and recycling waste, 3M estimates that it prevented the generation of more than 3 billion pounds of pollutants and saved nearly $1.4 billion in the first year alone.

According to a 2010 study by the Hague Centre for Strategic Studies, public–private partnerships appear to be the most common policy tool used by nations to maintain the supply of element and mineral resources. Japan, for example, has instituted an Element Strategy Initiative based on four pillars: 1) substitution (of an endangered element for a more readily available one), 2) regulation (to avoid shortages and chemical hazards), 3) reduction (e.g., by increasing process efficiencies in manufacturing), and 4) recovery (including recycling and urban mining).

Citizens can contribute in a very personal way to re-mining in their local communities.Material scientists are tackling elemental substitution on many fronts. In one example, they have discovered that when common nitrogen is added appropriately to a form of carbon known as graphene, a catalyst results that could substitute for the platinum catalyst currently used in clean fuel-cell vehicles. And within five years, chemists may be able to develop a replacement for the endangered rare earth neodymium, widely used in magnets.

Meanwhile, citizens can contribute in a very personal way to re-mining in their local communities. Urine is phosphorus rich and a natural consequence of human food production. Two Swedish cities now require the use of toilets that separate urine from solids as a step toward realizing the Swedish government’s goal of re-mining 60 percent of the phosphorus contained in sewage by 2015. Doing so will obtain a source of phosphorus native to Sweden, augmenting imported phosphate rock.

Systems Approach

Effective strategies to further achieve elemental sustainability and concomitant benefits will require a systems approach that examines all facets of the consumer cycle as well as market and nonmarket approaches to properly account for the true, full value of linked element-energy-environment resource use. Initial steps can be taken now by:

- taking better stock of the rich veins of chemical elements tied up in our consumer goods and discarded into waste streams

- reducing unnecessary consumption

- increasing the efficiency with which we use the most endangered elements

- substituting into consumer goods elements that are more readily available and more easily re-mined

- improving the efficiency of reextraction of the elements from urban mines

- designing and engineering for a closed life cycle of elements — extraction, production, consumption and reextraction for further reuse

- developing new relationships between suppliers (re-miners), producers, manufacturers and consumers to effectively transport materials from those who see it as waste to those who see it as a resource.

But perhaps most importantly, achieving sustainable use of elements will require re-visioning our interaction with rural and urban environments, our concept of mining, and our attitudes toward waste. Consumption will need to be seen as a continuous cycle: a cycle with no off ramps for trash, junk or waste. What we now call our possessions, our homes, our cities, our soil, our organic waste and urban scrap heaps are not (permanent) ends, but very literally the means to the next cycle of human consumption — the banks that hold our globally shared reserves of precious chemical elements.

![]()

Editor’s note: The views expressed here are those of the author and not necessarily of Ensia. We present them to further discussion around important topics. We encourage you to respond with a comment below, following our commenting guidelines, which can be found here. In addition, you might consider submitting a Voices piece of your own. See Ensia’s “Contact” page for submission guidelines.

Ensia shares solutions-focused stories free of charge through our online magazine and partner media. That means audiences around the world have ready access to stories that can — and do — help them shape a better future. If you value our work, please show your support today.

Yes, I'll support Ensia!