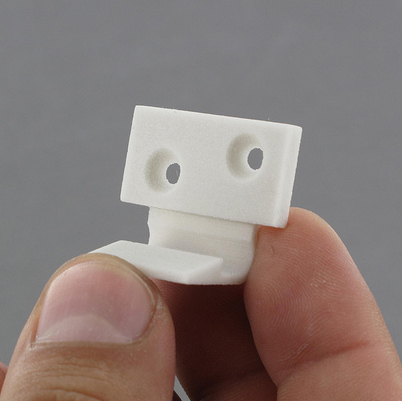

October 8, 2013 — Which is more environmentally friendly: purchasing mass-produced small plastic components or making your own using a 3-D printer? Michigan Tech researchers did a life-cycle analysis of the energy inputs for three plastic products — a toy block, a juicer and a water spout — starting with extraction of raw materials and ending with either a final product printed at home or a product shipped from an overseas manufacturer to a U.S. port. They found that, contrary to expectations, producing an object with 3-D manufacturing uses 41 to 64 percent less energy and has a correspondingly smaller carbon footprint than mass producing and shipping that same object from overseas. Project leader Joshua Pearce notes 3-D printing is cheaper, too — providing even more motivation for foraying into the brave new world of do-it-yourself stuff. Photo by Creative Tools (Flickr | Creative Commons)

Ensia shares solutions-focused stories free of charge through our online magazine and partner media. That means audiences around the world have ready access to stories that can — and do — help them shape a better future. If you value our work, please show your support today.

Yes, I'll support Ensia!