April 7, 2016 — Editor’s note: This feature was adapted and reprinted with permission from Cosmos magazine. View the original here.

Mention “carbon capture and storage” — the process of trapping carbon dioxide produced in fossil-fuel burning or other industrial processes and burying it underground — in polite company, and you’re likely to be pounced on. It’s absurdly expensive. It can never be rolled out en masse. Storing massive amounts of CO2 below ground sounds risky. And it’s too late: Wind and solar have left it in the dust. The clear unassailable death knell, say the critics, is that even the fossil fuel industry, the biggest beneficiary, hasn’t embraced the technology.

It’s hard to find a friend for carbon capture and storage. Regulators and governments — though eager to subsidize solar or wind power — offer no such encouragement to capture carbon. Last November, the U.K. government, a one-time champion, stuck in the knife by cancelling a billion-pound (US$1.4 billion) fund earmarked for rolling out CCS.

That’s the tough reality for the chemists, geologists and engineers developing CCS for the past 20 years. When they began they were tarred as collaborators of the fossil fuel empire or as Don Quixotes chasing an impossible dream. Now their ugly duckling technology is ready to fly. And it’s having a very tough time spreading its wings.

But that may be changing. The lead-up to the Paris climate talks last year produced many road maps designed to steer the planet away from the cliff of 2 °C (3.6 °F) of warming. In each one, nestled among the windmills and solar farms, was the ugly duckling. Take it out of the equation and the costs of meeting the 2°C (3.6 °F) target would more than double.

Besides, as most of the road maps pointed out, even without coal- or gas-fired power stations, industrial processes, including steel and cement manufacturing, generate 15 percent of CO2 emissions. And combusting biomass, rather than coal, in a CCS power station could create “negative” emissions.

In report after report, fossil fuel industry groups and green non-governmental organizations supported CCS. “CCS could deliver 13% of the cumulative emissions reductions needed by 2050 to limit the global increase in temperature to 2 °C,” declared the International Energy Agency, a support group for energy-producing nations with a commitment to sustainable solutions.

At the very least, Paris seems to have made CCS a respectable topic. “CCS plays a vital role as part of an economically sustainable route to meet climate mitigation goals with the 2050 time frame,” noted Miguel Arias Cañete, the EU commissioner for Climate Action and Energy, in a recent Global CCS Institute report. Even a coalition of climate non-governmental organizations with impeccably green credentials released a report titled Closing the Gap on Climate: Why CCS is a Vital Part of the Solution.

At the very least, Paris seems to have made CCS a respectable topic. Is it possible CCS will take flight at last?

Something Old, Something New

CCS is not new. Its first adherent was the natural gas industry, where CO2 is often found mixed with methane. Concentrations of CO2 can be as high as 50 percent or more and must be filtered out to maintain gas quality.

Companies had been pumping gas out of the European North West Shelf for decades and venting waste CO2 into the atmosphere. Then in 1991, Norway put a price on CO2 emissions.

That led to the Sleipner project. In 1996 energy company Statoil initiated the world’s first commercial CCS project, pumping separated CO2 back into the undersea sandstone beds it came from. “They did the sums and decided it was cheaper to put the stuff in the ground,” explains geologist Peter Cook.

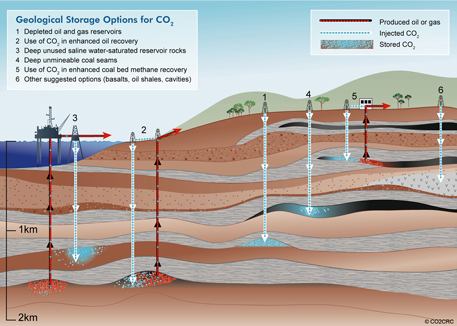

Options being explored for storing CO2 underground include depleted oil reservoirs and deep underground cavities. Image © CO2CRC

British born Cook first encountered Sleipner as director of the British geological survey in the mid-1990s. Could this technology be the answer to all fossil fuel emissions? “It was clear to me we really needed to look at this more closely,” Cook says.

His chance came in 1998 when he was offered the job of directing the Australian Petroleum Cooperative Research Centre. Cook managed to convince the board to start a program looking at the feasibility of geologically storing CO2.

Petroleum and gas producers wanted to sequester CO2 from oil and gas fields. But Cook also thought about Australia’s dependence on coal. The state of Victoria was 90 percent dependent on brown coal. Its Hazelwood power station in the Latrobe Valley produced among the highest carbon emissions per kilowatt of electricity in the world.

Cook’s program, GEODISC (Geological Disposal of CO2), investigated whether Australia had enough suitable rocks for storing CO2. Such rocks are known as saline aquifers. They have a layer cake structure with porous sandy watery slabs that have a great capacity to store CO2, topped by a nonporous mudstone layer to seal it in.

The scheme was not popular: “I was perhaps seen as a caricature of a geologist who would rape and pillage the Earth,” recalls Cook.

Nevertheless, GEODISC produced impressive results. It turns out that Australia has “world class rocks,” he says. The project built so much momentum that in 2003 it became the launch pad for a new cooperative research center devoted to carbon capture and storage — the CRC for Greenhouse Gas Technologies, or CO2CRC. Cook was appointed director.

If capturing natural gas emissions is like netting a flock of butterflies, capturing coal emissions is the more difficult task of chasing a lone flutterer.Cook had command of the storage technology. But “capture” required a separation chemist. Cook recruited one with a stellar international record. Chemical and biomolecular engineer Geoff Stevens’ expertise lay in understanding the behavior of molecules at interfaces: What will make them jump from one solvent to another? He has separated opium from poppies, cobalt from ores, and as part of a tissue-engineering team, gases across membranes in artificial lung sacs: “It’s all the same basic process,” he says.

At Sleipner they capture CO2 by binding it to chemicals called amines; it’s neither difficult nor overly expensive. Natural gas spurts out of the ground as if from a fire hose — that high pressure helps drive CO2 capture. But the process is different for the vapors escaping a coal-fired power station at atmospheric pressure. If capturing natural gas emissions is like netting a flock of butterflies, capturing coal emissions is the more difficult task of chasing a lone flutterer.

Various capture methods were tested at CO2CRC. Some were variations on the amine theme; others employed carbonates. The CO2 traps might be attached to the flue gases emerging from the combustion of coal. Collectively this method is called “post-combustion capture.”

A second method increases the efficiency of capture by burning the coal in oxygen and recycled flue gas, a method dubbed “oxycombustion.” The flue gas ends up as a mixture of CO2 and steam. Allowing the steam to cool and condense leaves a stream of CO2 concentrated at around 85–90 percent.

A third method, “pre-combustion capture” involves capturing carbon before it is burned. Surprisingly, if coal is baked under steamy conditions at 700 °C (1,000 °F), it vaporizes into syngas: a mixture of carbon monoxide, carbon dioxide and hydrogen. Known as “gasification,” this is a time-honored technique for producing transportable fuel when oil is in short supply. When coal is gasified, CO2 is produced at a pressure 20–40 times higher than that in a coal flue, making it more efficient to separate. The hydrogen fuel is then burned in a carbon-emission-free turbine that resembles a jet engine.

The Storage Question

Capturing millions of tons of CO2 is only the first part of the solution. Fifteen facilities are now capturing CO2. Most are connected to natural gas, but others are linked to fertilizer and ethanol production or turning Canadian oil sands bitumen into synthetic crude, as does Shell’s Quest project.

According to the International Energy Agency, these projects capture 27 million metric tons (30 million tons) of CO2 per year. But to stay below 2 °C this will have to ramp up to 6,000 million metric tons (7 billion tons) per year by 2050 — contributing one-seventh of the total emission savings required, according to the IEA.

Geologist Sally Benson and colleague Jean-Christophe Perrin use a medical CT-scanner to study rocks’ ability to store CO2. Photo by Anne Knudsen

That means our planet would have to store billions of tons of CO2, safely and forever. Is this possible? Not everyone thought so.

Sally Benson is a calmly spoken Stanford University geologist who studies how CO2 moves through saline aquifers. She is also the director of the Global Climate and Energy Project — a university–industry partnership whose remit includes comparing the performance of various low-emissions technologies.

But in the early 2000s she was director of Earth Sciences at the Lawrence Livermore National Laboratory in California, and a CCS skeptic. “I thought that’s the silliest thing I ever heard,” she recalls. She was convinced rocks held enough storage capacity for only 10 to 20 years. Then she started collecting data for a paper and reached a different conclusion: the storage capacity was in excess of 300 years, long enough to be useful until zero emissions technologies take over. She has since become a CCS champion. In 2005, she was a lead author for what remains the definitive report on the technology’s potential: the Intergovernmental Panel for Climate Change Special Report on Carbon Dioxide Capture and Storage. Cook was also an author; both were part of a group that received a Nobel Peace Prize for their efforts.

Cook and Benson belong to a passionate and beleaguered minority who believe CCS is a crucial part of the toolkit to keep the planet safe. But the tool needs testing and the geologists have their work cut out.

Nestled in scenic farmland 40 kilometers east of the coastal town of Warrnambool, Victoria, lies a world-leading research facility. A fenced-off network of pipes pokes out of the ground, at the bottom of which lies 65,000 metric tons (72,000 tons) of pressurized liquid CO2 more than a kilometer below the surface. This is the Otway project, the latest incarnation of CO2CRC.

“Absolute perfection is required,” says program manager Matthias Raab, gesturing at the engineers flocked around a crane that is carefully feeding an insulated wire down a 1.5-kilometer-long (0.9-mile-long) pipe, like a catheter into a patient’s vein.

The pipe terminates at a salt-water impregnated rock layer that has received 65,000 metric tons (72,000 tons) of CO2 injections. This is the Waarre C aquifer; its vital signs are monitored by sensors on the wire. Meanwhile on the surface, the thumps of “seismic” trucks build a 3-D image of the rock layers from sound wave reverberations.

Why the need to develop such detailed information about what CO2 will do underground? Mistakes are costly. In the 1950s, proliferating oil derricks caused Long Beach, California, to sink by meters. That’s why oil companies employ geologists to model the subsurface. The same care is required when injecting CO2, says German geologist Stephan Matthai, who leads the reservoir engineering team.

Uncertain Future

The future of CCS projects is uncertain. They remain unpopular with the public — as Matthai knows from experience. In 2009, he was an advisor to the Austrian government on carbon storage. Hostile media likened it to storing nuclear waste. First the German government gave up on CCS; two years later the Austrians followed suit. “It was really unfortunate,” Matthai says.

Benson says from 2004 to 2008, the years before the 2009 Copenhagen climate summit, were good for CCS globally: “People believed in the technology. We got government money and good attention. Everyone believed a global carbon policy was imminent so the context was to start planning.”

Then came the global financial crisis in 2008 and the failure of the Copenhagen Summit to set any emissions targets in 2009. Things turned gloomy for CCS. In these circumstances, who would want to invest in the technology?

Canada’s SaskPower did, in the capture technology, at least — partly because it was state-owned and anticipated an imminent carbon tax, but there was another economic rationale. A stream of pure, pressurized CO2 is valuable — worth around US$20-40 per metric ton ($US20–40 per ton). You can sell it to soft drink manufacturers, or to chemical plants to make ammonia or plastics. Or to oil companies: Across the U.S. much of the free-flowing oil is long gone from wells. What remains is the viscous dregs. CO2 acts like a detergent and flushes the oil out. SaskPower sells Boundary Dam’s CO2 to the nearby Weyburn oil field, where it should yield an extra 130 million barrels over the next 25 years.

But offsetting the price of CCS by producing more oil does nothing to help its public image.

And the prospects for CCS were not helped by the apparent death of King Coal in Europe. In Italy, for instance, coal-fired power stations were turned into museums. But elsewhere there was a coal renaissance — and for good reason. Manufacturing relocated to developing countries. According to a July 2015 report from the Mercator Research Institute on Global Commons and Climate Change, India, China and other Asian and African nations increased their coal consumption 3.7-fold between 1990 and 2011. Some exploited their own coal; others imported it from countries such as Australia because it was so cheap. India is preparing to provide electricity for nearly 600 million new consumers by 2040 while ramping up its “Make in India” program.

“If people want to cut emissions yet go on using fossil fuels, we need the technology.” – Peter CookAnd while coal consumption has slowed in China, which will likely hit peak coal well before its promised date of 2030, it will continue emitting vast amounts of CO2 before then. China and India plan to build more than 1,600 new coal-fired power plants between them by 2030, according to the online Global Coal Plant Tracker.

Making CCS Respectable

The future for CCS looked so bleak in 2015 we seriously questioned if it was worth writing about. But the Paris conference may have changed the conversation. The signatories agreed that the world needs to achieve zero emissions by 2050. And even if the entire planet manages to switch to renewables and nuclear energy overnight, we would still be emitting CO2 through industrial processes.

Even so, the CCS costs are daunting. Where will the money come from?

For the moment all eyes are on China. Robin Batterham, a former group chief scientist at mining giant Rio Tinto, is a consultant on various Chinese projects. He predicts the costs will fall as more plants are rolled out: “It’s just a universal law — if you build it at scale you discover tricks. We don’t know the real cost of CCS.”

Batterham says the rapid roll out of China’s new fleet of ultra-supercritical plants is evidence of what’s possible. The plants are designed to scrub air pollutants, not CO2. But they are more efficient than standard coal plants, and reduce CO2 emissions by 30 percent. “The experience in China is they go ahead and build a large demo plant and many more follow,” Batterham says.

If China decrees a carbon tax in 2017, Stevens is confident the new fleet will be fitted with post-capture techniques: “They are not going to dismantle these investments that will still have decades of life in them.”

The Paris conference was hailed as historic for at last securing commitments from 195 countries to reduce their emissions. But another part of its legacy may be to have made CCS respectable.

Cook, a self-confessed “born optimist,” is convinced CCS will be rolled out in the next five years: “If people want to cut emissions yet go on using fossil fuels, we need the technology. There’s a certain logic there I find compelling.”

Benson is optimistic, too: “CCS is at the same place solar cells were two decades ago. Look how far we’ve come. CCS dead? It’s not even born yet.” ![]()

Ensia shares solutions-focused stories free of charge through our online magazine and partner media. That means audiences around the world have ready access to stories that can — and do — help them shape a better future. If you value our work, please show your support today.

Yes, I'll support Ensia!