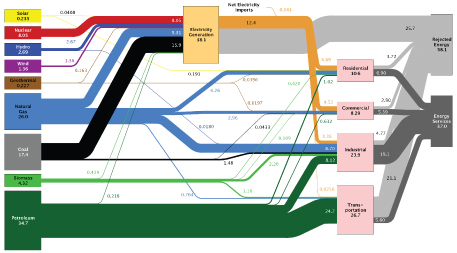

December 18, 2013 — Every year, the Lawrence Livermore National Laboratory produces a visual depiction of how energy flows through the American economy. Energy sources appear on the left and follow colorful paths to their eventual uses on the right of the chart.

Even though I spend much of my time thinking about energy, it’s always shocking to see, year after year, the wide gray swath of so-called “Rejected Energy” heading toward the top right. In reality, that’s just a polite way of saying there’s a lot of waste in the energy system — especially at coal-burning power plants.

Estimated U.S. Energy Use in 2012: ~95.1 Quads. Image courtesy of Lawrence Livermore National Laboratory. [Click to enlarge.]

Imagine it this way: Coal trains barrel by as you stand on an overpass above the tracks. The power system’s inefficiency means that every three boxcars out of four are really hauling waste — only one boxcar is hauling the source of the juice that gets to your electric socket. At large coal plants, as many as four trainloads of coal might arrive each day. The wastefulness of coal combustion is not only costly, it also results in huge quantities of greenhouse gas emissions, the main reason coal retirement is always near the top of the list of carbon-reduction strategies.

But it is possible for a power plant to turn a higher percentage of its energy input into usable energy output — 60 to 80 percent, in fact — thereby becoming more efficient and less carbon intensive. This is exactly what combined-heat-and-power plants do, by generating electricity for the grid and using thermal energy to heat a city or power industrial processes nearby. This kind of plant is typically smaller than coal-burning plants and located where heat energy is needed. A good example is in my hometown, St. Paul, Minn. District Energy St. Paul heats about 80 percent of downtown and supplies electricity to the grid right in the heart of the central business district using wood waste from the urban forest here.

Going back to the train analogy, it stands to reason that if we tripled system efficiency to 75 percent, we’d now have three boxcars of coal that provide useful energy, and only one boxcar that hauls only waste and pollution. That means we’d cut carbon dioxide from waste by two-thirds.

So, why not just build or retrofit coal-burning plants with CHP technology and call it a day? Because coal power plants tend to be big (typically 500 to 1,000 megawatts) and therefore not in proximity to “customers” — like cities — that could use the thermal energy produced. In North Dakota, for example, the new Spiritwood plant is scheduled to be a coal-burning CHP plant of only 99 MW. Start-up at Spiritwood has been delayed for years at enormous financial cost while the owner recruits huge industrial customers with a need for all of that thermal energy to move near the plant.

I’d advocate for using a renewable fuel, such as biomass, in CHP plants, taking us even one more step away from grossly polluting coal-burning power plants.

Natural gas plants, however, can be much smaller. Because their small scale and modularity allow them to be easily built in areas where customers are already in place to use the thermal energy, natural gas CHP plants make sense. So, where CHP plants do exist in the U.S. today, most use natural gas, coupling low pollution (natural gas is a much lower-carbon fuel than coal) and high efficiency. This is two steps in the right direction — not only away from coal-burning power plants, but also toward using waste heat productively. Still, in a world seeking to drive carbon emissions to near zero, it may not be good enough.

I’d advocate for using a renewable fuel, such as biomass, in CHP plants, taking us even one more step away from grossly polluting coal-burning power plants. Imagine a 75 percent efficient power plant that uses a sustainably harvested fuel. Going still greener, we should borrow an idea from the carbon-capture crowd: capture and store the CO2 emissions from biomass CHP. This kind of power plant would be carbon negative, stashing away CO2 underground that plant matter (used as biomass fuel) absorbed while it grew.

How amazing is that: a power plant that reduces global warming, instead of making it worse?

While hundreds of European cities use biomass CHP already, it’s still rare in the U.S. That said, several good examples are within three hours’ drive of my office. I already mentioned the use of wood waste here in St. Paul. Rahr Malting partners with the Shakopee Mdewakanton Sioux Community to use waste barley hulls from the malting factory to make electricity, while the waste heat sprouts the malt to make beer. In northern Minnesota cities of Virginia and Hibbing, wood waste from forestry operations makes electricity and heats the towns, and other CHP plants power paper mills nearby.

Without an established price on carbon emissions, biomass CHP is still an economic reach, and capturing and storing CO2 is even more economically difficult. But, as science already understands, to stay under the danger threshold for the climate, we’ll need technologies that remove CO2 from the Earth’s atmosphere. Ultimately, state-by-state, city-by-city, utility-by-utility and regulator-by-regulator commitments will be required to get out of the inefficient coal-burning business, which will drive opportunities for new renewable generation. Despite competition from wind and solar power, with their rapid cost declines, biomass CHP with carbon capture should be on the short list of carbon-negative strategies for a coal-free future.

![]()

Editor’s note: The views expressed here are those of the author and not necessarily of Ensia. We present them to further discussion around important topics. We encourage you to respond with a comment below, following our commenting guidelines, which can be found here. In addition, you might consider submitting a Voices piece of your own. See Ensia’s “Contact” page for submission guidelines.

Ensia shares solutions-focused stories free of charge through our online magazine and partner media. That means audiences around the world have ready access to stories that can — and do — help them shape a better future. If you value our work, please show your support today.

Yes, I'll support Ensia!

You should not compare the efficiency of generating electricity and heat from a combined heat and power plant with that of the electricity generated from a coal plant.

Instead you should compare it with the efficiency of electricity generated from a coal and the efficiency of heat generated by a gas furnace. That is the system a CHP plant would replace. Gas furnaces are ultra efficient. Most new ones around 90%.

As a result the overall efficiency increase is not a factor of three as you claim. Instea it is much less than 100%, and probably below 50%.

http://www.epa.gov/chp/basic/methods.html

Paraphrasing Einstein, problems can't be solved with the thinking that created them. A combined heat/power system, like all distributed generation solutions brings so much more to the game than a mere efficiency comparision. Reimagining the on-site energy solution and valuing the benefits of this type of system brings many other valuable business solutions for the user: redesigning systems can offer higher reliability, potentially lower costs, business continuity benefits and more. Moreover, many of those issues are currently paid for by the business (back-up generators for example) that could be economized in a holistic design. New thinking about the business value of on-site generation should lead to redesigning facility infrastructures to maximize these new benefits - addressing the global efficiency issue in the article and delivering much higher value for the user.